One of the many challenges of tomato (Solanum lycopersicum L.) and kale (Brassica oleracea) greenhouse growers is the management of edema (oedema). Often described as intumescence or enations, edema is an abiotic-induced complication that develops at different levels of intensity

depending on the cultivar and, in some cases, between individual plants.

Symptoms

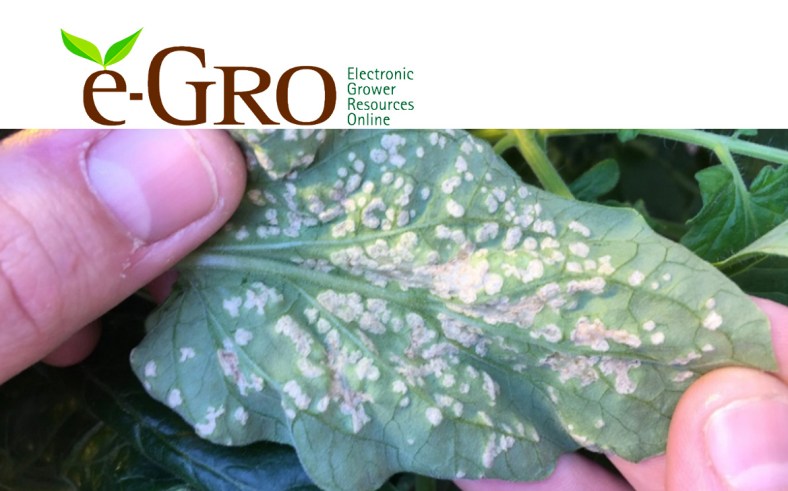

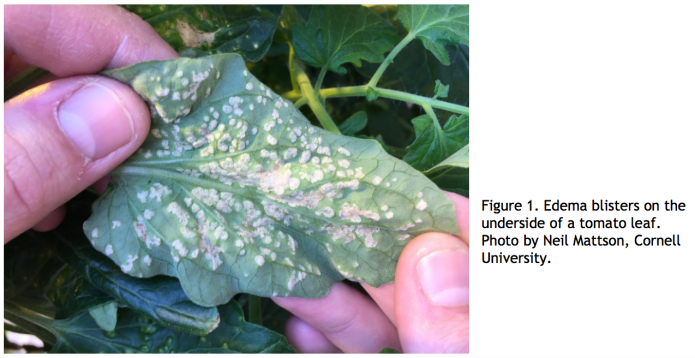

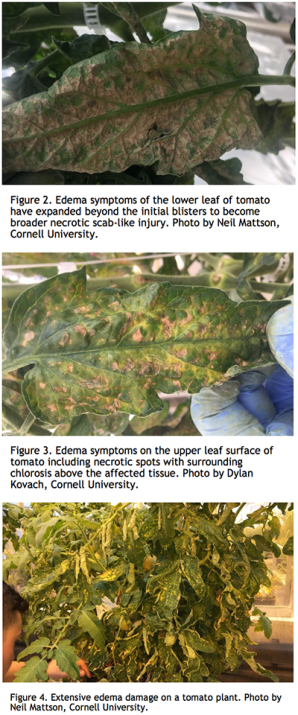

Edema is often described as a blister or callus-like formation that forms predominately on the bottom of leaves (Figure 1).

This swelling is the result of the epidermal layer on the leaf expanding due to cellular elongation, which eventually burst as cells reach their limits of expansion.

The resulting damage on the bottom-side of the leaf can be characterized by dark brown, tan, or even yellow necrotic tissue on the surface of the leaf that expands past the original location of the blister as a scab-like injury (Figure 2). On the upper side, necrotic spots mark the location of the ruptured intumescence below, while the surrounding tissue is generally

chlorotic (Figure 3). Tissue affected by edema is brittle, with the leaf structure cracking under gentle pressure by the fingers. Extensive edema can severely decrease the leaf’s photosynthetic capability and lead to senescence (Figure 4).

Causes

The cause of edema can be linked to a variety of environmental conditions. The long-standing suggested cause of intumescence is the buildup of excess

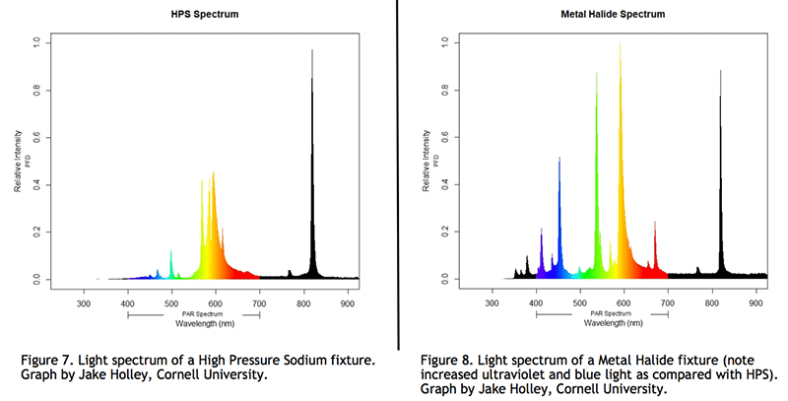

moisture in the root medium paired with conditions favorable to low transpiration (i.e. high humidity). In a study conducted by Kansas State in 20091, it was concluded that the water content of the root zone may influence the development of edema in tomatoes. Other research has pointed to light quality (lack of ultraviolet light) being a driving force behind the development of edema in Northern greenhouse tomato production. Due to largely overcast, low light conditions during winter months, most of the lighting provided to tomato crops in greenhouse operations are supplied by high pressure sodium (HPS) fixtures. While these units produce significant amounts of light in the yellow/red spectrum (550 – 650 nm), they lack in short wavelength energy (300 – 400 nm) (Figure 7). This shortwave energy is also lost in greenhouses constructed with glass glazing which has relatively low transmissivity of UV light as compared with polyethylene glazing.

In the same study by Kansas State, it was found that UVB helps prevent the formation of intumescence. In another experiment, conducted at the University of Arizona2, using small doses of end-of-day far red (EOD-FR) and a 75% blue light ratio led to a decrease of intumescence injury from 62-70% of leaves being symptomatic to only 5%. Work at Michigan State University3, found dramatically reduced edema symptoms when light with

50:50 Blue:Red ratio was used as compared with 100% Red light.

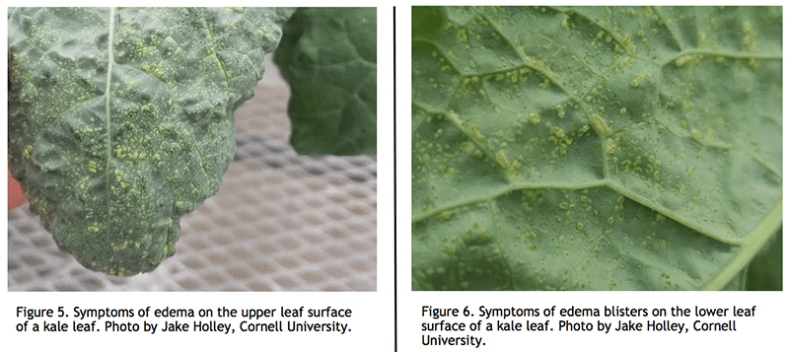

Edema of Kale

In kale, sudden increases in humidity can cause edema, often coinciding with outdoor weather like rain. Edema can be especially impactful on kale crops as the superficial appearance of leaves affects their marketability (Figures 5 and 6). Maintaining a low relatively humidity within greenhouse environments and changing management strategies to better cope with outdoor weather will help prevent edema in kale. This may include increasing shading within a greenhouse to reduce use of cooling pads to help manage humidity. Changes to irrigation timing and application or spacing plants further apart may also help to reduce humidity.

Solutions

Controlling the impact of edema should be done on a case-by-case basis for each operation and based on likely causes. As mentioned before, the severity of intumescence on tomatoes is largely dependent on the susceptibility of the cultivar and individual plants. If the crop is experiencing major leaf senescence and poor yields, it may justify the cost to invest in preventative measures. Most modern lighting fixtures with digital ballasts can run both high pressure sodium and metal halide (MH) bulbs. For older magnetic ballasts, conversion bulbs can be purchased that also allow you to utilize MH bulbs in an HPS fixture. While somewhat less efficient and shorter lived, the benefit of metal halide is it provides more of a “full-spectrum” light output, with significantly more short wavelength energy (Figures 7 and 8). This strategy combining HPS and metal halide could reduce the onset of edema-like symptoms. While a considerably costlier investment, LED fixtures offer the greatest flexibility in light quality. As prices decrease and efficiency increases, LED technology may offer the solution to improved yields through the reduction in intumescence frequency.

For many other growers, the prevalence of edema may not justify the investment of retrofitting an entire greenhouse. One preventative measure that can be taken to reduce the risk of edema is ensuring the proper environmental conditions of a greenhouse. This includes the ventilation of excessive humidity, proper use of supplemental lighting during periods of low ambient lighting, and irrigation management (to avoid saturating the root zone). It may also be beneficial to experiment with a variety of cultivars to screen for edema-like symptoms or work with a seed distributor on selecting cultivars that are less sensitive to edema. No matter the situation, it is advantageous to develop an action threshold to determine at what level of prevalence should you address the issue of edema in your operation.

Citations

1Rudd, N. (2009). Environmental Factors Influencing the Physiological Disorders of Edema on Ivy Geranium (Pelargonium Peltatum) and Intumescences on Tomato (Solanum Lycopersicum) (Masters of Science). Kansas State University.

2Eguchi, T., Hernández, R. and Kubota, C., 2016. Far-red and blue light synergistically mitigate intumescence injury of tomato plants grown under ultraviolet-deficit light environment. HortScience, 51(6), pp.712-719.

3Wollaeger, H., & Runkle, E. (2014). Does light quality impact the development of edema? Retrieved from https://www.canr.msu.edu/news/does_light_quality_impact_the_development_of_edema

e-GROAlert

www.e-gro.org

CONTRIBUTORS

Dr. Nora Catlin, FloricultureSpecialist

Cornell Cooperative Extension, Suffolk County, nora.catlin@cornell.edu

Dr. Chris Currey, Assistant Professor of Floriculture

Iowa State University, ccurrey@iastate.edu

Dr. Ryan Dickson, Greenhouse Horticulture and

Controlled-Environment Agriculture, University of Arkansas, ryand@uark.edu

Nick Flax, Commercial Horticulture Educator

Penn State Extension, nzf123@psu.edu

Thomas Ford, Commercial Horticulture Educator, Penn State Extension, tgf2@psu.edu

Dan Gilrein, Entomology Specialist, Cornell Cooperative Extension

Suffolk County, dog1@cornell.edu

Dr. Joyce Latimer, Floriculture Extension & Research

Virginia Tech, jlatime@vt.edu

HeidiLindberg, Floriculture Extension Educator

Michigan State University, wolleage@anr.msu.edu

Dr. Roberto Lopez, Floriculture Extension & Research

Michigan State University, rglopez@msu.edu

Dr. Neil Mattson, Greenhouse Research & Extension

Cornell University, neil.mattson@cornell.edu

Dr. W. Garrett Owen, Floriculture Outreach Specialist

Michigan State University, wgowen@msu.edu

Dr. Rosa E. Raudales, Greenhouse Extension Specialist

University of Connecticut, rosa.raudales@uconn.edu

Dr. Beth Scheckelhoff, Extension Educator – GreenhouseSystems

The Ohio State University, scheckelhoff.11@osu.edu

Dr. Paul Thomas, Floriculture Extension & Research

University of Georgia, pathomas@uga.edu

Dr. Ariana Torres-Bravo, Horticulture/ Ag. Economics

PurdueUniversity, torres2@purdue.edu

Dr. Brian Whipker, Floriculture Extension & Research

NC State University, bwhipker@ncsu.edu

Dr. Jean Williams-Woodward, Ornamental Extension Plant Pathologist

University of Georgia, jwoodwar@uga.edu

Copyright ©2019

Where trade names, proprietary products, or specific equipment are listed, no discrimination is intended and no endorsement, guarantee or warranty is implied by the authors, universities or associations.