Horticultural lighting researchers are asking for industry feedback on a proposed performance label that would provide uniform information on lamps used for horticultural applications.

How much easier would it be if growers had a standardized label that could be used to compare lamp performance metrics for horticultural applications? Growers interested in comparing the performance between different light-emitting diodes (LEDs) or comparing LEDs to high pressure sodium lamps (HPS) would be able to look at the lamp labels to determine which meets their production needs.

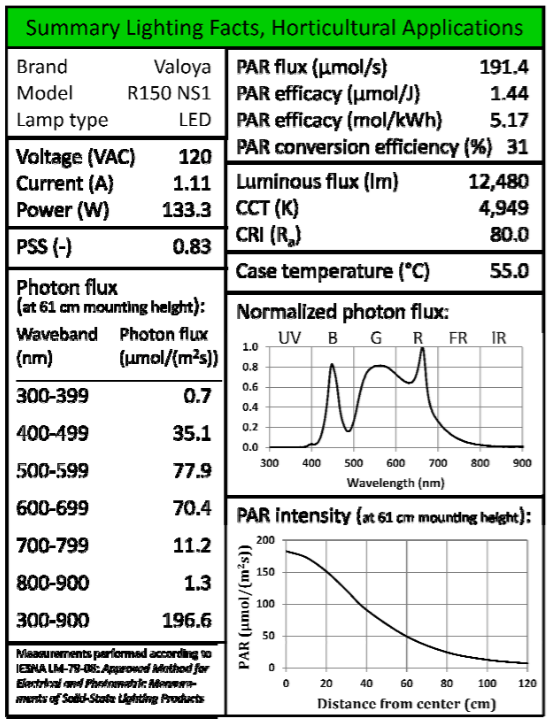

Horticultural researchers at several U.S. universities have developed a proposed standardized product label that would allow for the comparison of manufacturers’ lamps that would have application to all lamps used for horticultural applications. The label includes the efficacy (output of photosynthetically active radiation per unit of electric power consumed measured in micromoles per joule (μmol/J), conversion efficiency, photon flux output in key wavebands in 100 nanometer (nm) increments across the 300-900 nm waveband, the phytochrome photostationary state, and graphs of the normalized photon flux across the 300‐900 nm waveband, as well as the light intensity distribution at a specific distance from the light source.

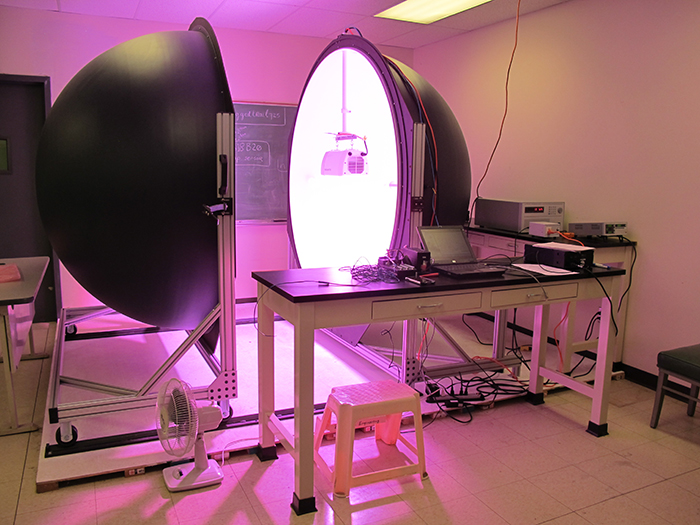

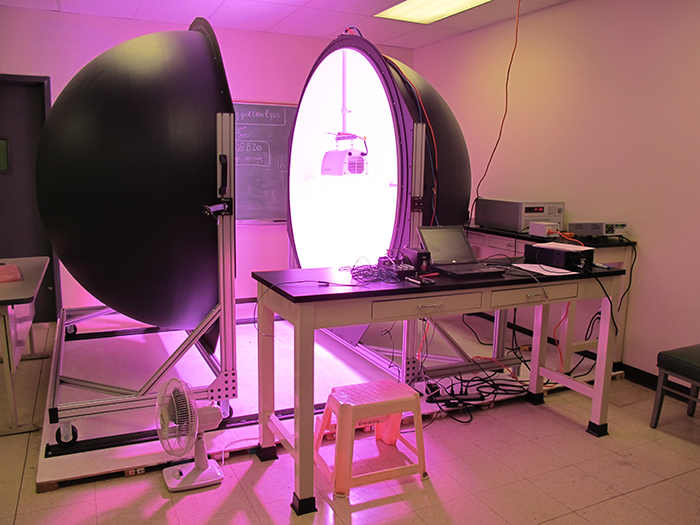

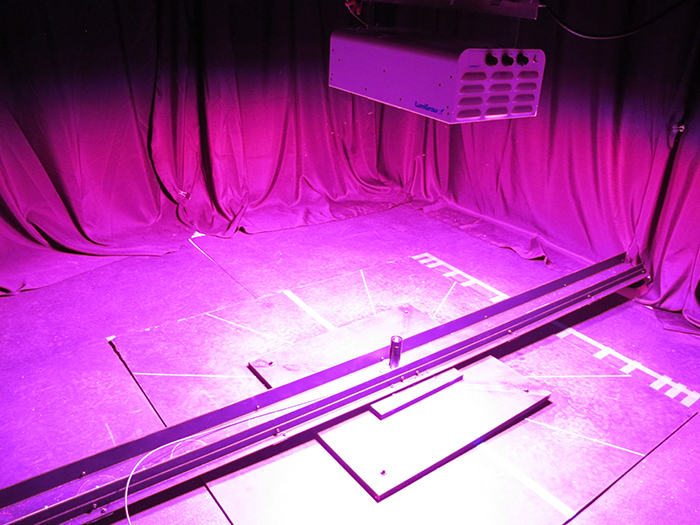

Photos by A.J. Both, Rutgers Univ.

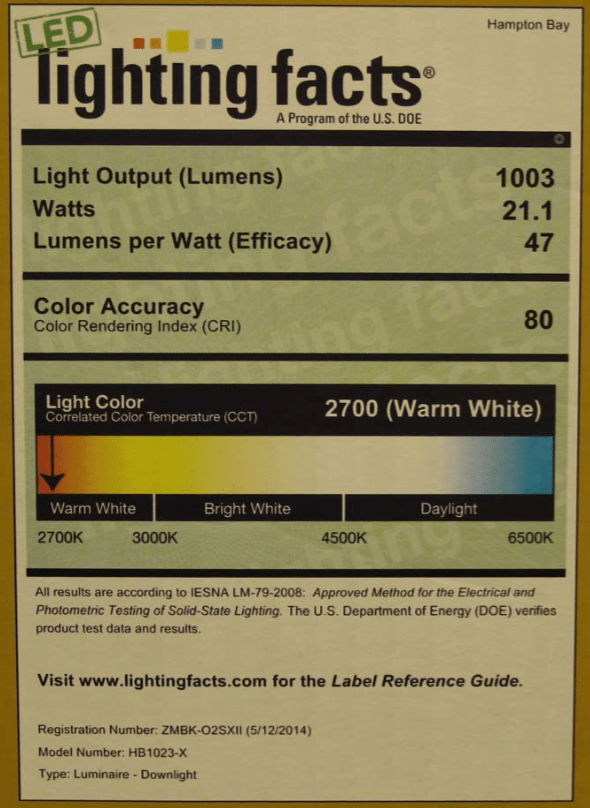

“Any time a consumer buys a light bulb there is a label on it that was designed and promoted by the Department of Energy,” said agricultural engineer A.J. Both, who is associate extension specialist at Rutgers University. “This was our starting point. In the case of horticultural lamps, the end users have much different interests than consumers who are buying light bulbs for their homes and businesses. The university researchers that worked on this label had to decide what was the important information that would be useful for greenhouse growers and other controlled environment users. This is how we came up with this particular label. Our intention is that the label can be used for all light sources used for horticultural applications.”

Pertinent light label information

Both said the light bulbs purchased by consumers have a minimal amount of information on the label.

“The consumer light bulb label tells how much light in regards to visible light that the unit puts out and how much energy (watts) it consumes,” he said. “It calculates the efficiency in lumens per watt.

“In the case of a horticultural light more information is needed. We need to know something about the different light wavebands that are being produced. The proposed label includes a table that shows the different wavebands. In regards to the amount of light, the label doesn’t use lumens or lux, it uses micromoles. The label also includes information about how light is being distributed. It includes a graph that shows when a light bulb is hung at a certain height what the light intensity is going to be as you move away from the center of the lamp. This provides the user a sense of how evenly or unevenly the light is being distributed.”

Both said whether the lamps are being used for photoperiod control or to increase photosynthesis, a grower needs to know specific information.

“A grower needs to know what particular spectrum a lamp is producing and how that light is being distributed,” he said. “In the case of photoperiod control, we’re not concerned about intensity. We’re only interested in the spectrum and the duration of the light. In the case of photosynthesis, we are interested in the intensity. For photosynthesis we want a high light intensity.”

Both said one metric that is difficult to determine is the lifespan of the bulb.

“Life expectancy is not on the label,” he said. “Manufacturers claim that LED lamps last much longer than the other lamps that are used for photosynthesis and photoperiod lighting. In order to do an independent test we would have to buy many different lamps and run them for many hours and then calculate what an average lifespan would be. That process would be very time consuming and expensive.

“Light manufacturers run the lamps for up to 6,000 to 10,000 hours and then use an algorithm to extrapolate from the data that they have collected what the life expectancy would be. That measurement requires sophisticated equipment and a special way of data collection. We didn’t go that far. So we are not making any claims about lifespan on the label. But it is a very important parameter that the grower would need to know.”

Both said one of the more challenging aspects of determining lamp life is the requirement that the lamp temperature should remain constant during the measurements.

“Keeping the temperature constant is a challenge because these lamps do generate heat, which has to be removed,” he said. “The temperature requirement is laid out in an official document (IES LM-80-08) that describes how to run these test measurements. The measurements are typically done over a time period of 6,000 to 10,000 operating hours. Manufacturers collect the data and then use a formula that calculates what the expected bulb lifespan would be. This process uses the so-called L70 value. This value represents the point in time at which the light output has dropped to 70 percent of the original light output. At that point manufacturers consider that the light has reached the end of its useful life. The L70 value tells users what the expected useful life of the lamp will be.”

Bulb information most important to growers

Both said the following metrics would be most import to growers who are looking to install horticultural lamps.

1. Photosynthetically active radiation (PAR) efficacy

“This number tells a grower how many moles of useful light in the PAR region are being produced per unit of energy that a grower pays for,” Both said. “The challenge is that very little independent research has been conducted into that number. We tried to measure some of these lamps and we contacted the manufacturers and asked them about their claims that their lamps’ efficacy, for example, was 2, where we found that the efficacy was only 1.75. Manufacturers now can claim whatever they want with regard to PAR efficacy. We are hoping that if the proposed label is adopted by the industry and PAR efficacy is posted on a manufacturer’s lamp label that this value will be based on some kind of independent evaluation so that growers know the value is accurate.

“Some manufacturers are providing a number for PAR efficacy. We have done some independent tests and found that the numbers were different then what they claimed. Typically we have found lower numbers. This is a major issue for growers who want to buy significant numbers of these lighting units. If the lights have a lower efficacy then the manufacturer claims, it is going to have a significant impact on the growers’ bottom line.”

2. Light fixture voltage

“The voltage a lighting fixture operates at affects the wiring a grower would need to install to supply the fixture,” Both said. “Does the fixture operate on 120 volts or can it be run at a higher voltage? Most growers would be interested in running at a higher voltage because that means there is a lower current requirement and that allows for thinner wires, which are typically less expensive than thicker wires.”

3. Weight of the light fixture

This information is not something that is included on the proposed label. Growers can obtain this information from the manufacturer. Heavier light fixtures need stronger supports.

4. Size of the light fixture

Growers will want to know how much space a fixture takes up and how much shading may result from it.

5. Light spectrum produced

Both said this is the elephant in the room. The light spectrum is a critical issue for growers.

“Many of the newer LEDs only provide red and blue light that produce this strange magenta color that can be difficult on the eyes,” he said. “This can make it difficult to make observations of the plants, including pest and disease symptoms or nutrient deficiencies.

“The spectrum also includes light distribution. How much light is produced in each waveband? How much blue light is there, how much red light is there?”

6. Light distribution

Both said light distribution is important because it indicates how easy or how difficult it is to produce a uniform light intensity over a specific growing area.

“If lamps have hot spots, for example, a high intensity directly beneath the lamp, moving away from the center the intensity typically drops off fairly quickly making it more difficult to design a uniform lighting system,” he said. “If the fixtures distribute the light more evenly, then it is much easier to produce a more uniform light intensity over a particular growing area.”

Seeking industry feedback

Both has submitted a manuscript about the proposed label to a scientific journal for publication.

“We want to make the horticulture industry aware of the proposed lighting label,” he said. “We hope to begin a dialog with the industry, including the manufacturers, and hope that they will participate by accepting this label. The first time I had an opportunity to present the label to the lighting manufacturers was at the horticulture lighting symposium at Michigan State University in May. There were several manufacturers that were interested in the label and wanted to discuss it more.

“Conferences like Cultivate’17 would be a good forum to discuss the label. That would be an industry venue where the label could be discussed with both growers and manufacturers. I expect my colleagues and co-authors of the paper, will talk about the lighting label at the various grower meetings they attend. I’m hoping we can use multiple ways to get information about the label out to the industry. Hopefully that will result in buy-in from the growers and the lighting manufacturers.”

For more: A.J. Both, Rutgers University, Department of Environmental Sciences, New Brunswick, NJ 08901; (848) 932-5730; both@aesop.rutgers.edu; http://aesop.rutgers.edu/~horteng

David Kuack is a freelance technical writer in Fort Worth, Texas; dkuack@gmail.com.