Originally published in Issue 4

With continuing concerns about water availability, safety and regulations, more growers are looking at water treatment to protect this vital resource.

The United Nations’ Intergovernmental Panel on Climate Change is scheduled to release a report on the impact of climate change in March 2014. A leaked copy of the final draft identifies key risks that could occur because of climate change. One of these key risks is related to the lack of availability of drinking and irrigation water to farmers and the impact it could have on their livelihood. The draft indicates that increasingly rising temperatures will reduce renewable water sources. Climate change is also expected to reduce raw water quality and to pose risks to drinking water quality. e panel advises that “adaptive water management techniques” could address the uncertainty caused by climate change.

Rising concerns over water availability and the potential for increased legislation related to water issues are causing more growers to look more closely at their water supplies. Proactive growers are determining how they can better use and protect their sources of water.

For many greenhouse vegetable growers collecting, recycling and reusing their water is critical to the success of their business. e increasing focus on food safety issues is also causing growers to examine the impact water treatment can have on the production, harvesting and handling of their crops.

The recycle movement

Charlie Hayes, founder and president of Advanced Treatment Technologies, said an in- creasing number of people in the greenhouse industry have accepted the fact that water will eventually have to be recycled.

“Some growers are already recycling their water and long term I think everyone will have to be moving in that direction,” he said. “Unfortunately, mistakes in how to accomplish this are going to occur. Growers stand the chance of damaging their whole crop with different forms of contaminants or with disease-causing organisms through recycling water that has not been effectively and appropriately treated.

“Understanding water treatment involves a lot of things, including types of filtration, types of oxidizers, dissolved oxygen levels, what is being le in the water and what is be- ing taken out of the water. A grower can take too much out of the water. For example, if a grower uses reverse osmosis, it puts a much bigger onus on him to make sure the proper nutrients for the plants are reintroduced into the water. is will require much more test- ing because there are some micronutrients in water that growers don’t consider when they are looking at fertilizers. Using RO water that is devoid of all ions will require a grower to make sure he puts back the nutrients that the plants are going to need.”

The goal of water treatment

Hayes said it doesn’t matter whether growers are producing edible or ornamental crops, they want the best quality water they can get for their plants.

“Looking at the incoming water for food crops, increasing regulatory mandates are requiring growers have potable quality water if it has the potential to ever contact the surface of the plants,” Hayes said. “ is could happen in any irrigation system that greenhouse vegetable growers are using, including troughs or channels and floating pond systems. e type of irrigation system won’t impact the quality of the incoming water, but if the water is in a closed loop system, the type of crop and production method will impact the water treatment system.”

Hayes said the goal of water treatment in most industries is twofold: 1.) to keep equipment, piping and delivery systems clean and 2.) to kill the potential pathogens in the water.

“My water treatment goal is very different,” he said. “My goal is to deliver water that is going to produce the healthiest plants possible. I have learned over the nearly 30 years of being a biochemist and studying water treatment that accomplishing that goal will take care of the other goals related to mechanical issues and the destruction of potential plant pathogens.”

While incorporating chemicals into their water supplies can keep the growers’ equipment clean and control pathogens, Hayes cautions that these same chemicals can have an adverse effect on the growers’ plants.

[adrotate banner=”23″]

“Plants can be sensitive to oxidizers,” he said. “Even though growers may not be seeing any negative effects on the plants, these chemicals may be affecting plant growth. The beneficial microbes around the plant roots may also be negatively impacted.”

Hayes said the most common oxidizers used for greenhouse vegetable crops include different forms of chlorine, chlorine dioxide, ozone and peroxide.

“Some oxidizers are more prone to phytotoxic effects than others,” he said. “With all oxidizers, it is a case of what is the target level, what level is being taken up by the plants and how well can that level be controlled? Many growers don’t understand and know what level of oxidizer residual is being delivered to their plants. is can occur with any of the oxidizers. e control system that is used to inject and monitor the oxidizer is critical. Some oxidizers are very pH sensitive and in order to work correctly the pH has to be within a narrow range. Other oxidizers create byproducts that can be phytotoxic or have negative eff ects on the plants depending on what inorganic or organic compounds are in the water.”

ects on the plants depending on what inorganic or organic compounds are in the water.”

Avoid a pieces-parts system

Hayes said a common mistake made by growers trying to install a water treatment system is they look at it as a component purchase.

“A grower thinks he needs a filter so he buys one and installs that into his irrigation system,” he said. “ Then the grower may consider adding an oxidizer to treat the water and adds that to his system. What eventually happens is the grower has installed a conglomeration of components that are dispersed throughout his system that were never designed to work together. Some of those components can cause problems for each other and sometimes they can leave gaps in the system.”

Hayes advises growers considering treating their water to work with companies that design water treatment processes and are not simply trying to sell treatment components.

“Very often growers don’t have the upfront capital to install a water treatment system all at once,” he said. “What I do is work with growers to determine where they are currently, where they could potentially be and determine the steps necessary to get them there, allowing them to take the right steps in the right order.”

Hayes said the process usually begins with the water source.

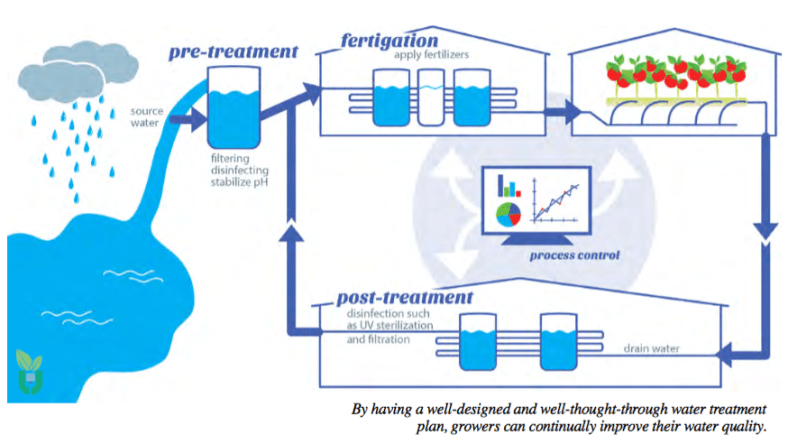

“Many growers are pulling from ponds that are collecting rain water runoff from their greenhouses,” he said. “It could start with something as simple as aerating the pond. en the grower might add beneficial organisms to the pond in order to prevent the buildup of pathogens and to ensure the breakdown of nutrients that need to be removed from the pond. By having a well-designed and well-thought-through plan growers can gradually and continually improve their water quality as they invest in their water treatment system.”

Monitoring is critical

Hayes said water sources change and they can get better and worse.

“Water sources can swing back and forth in the types of contaminants and pathogens that they contain,” he said. “ ese things should be monitored. Growers need to know their source water quality during the summer and winter. In addition, when growers do something to manipulate the water quality, they need to test, verify and monitor the water. If growers are not monitoring their water, they will never know that changes have occurred. They will see problems in the crop that they can’t explain because they weren’t monitoring their water quality both during and a er the treatment process.

Hayes recommends that growers monitor their in- coming source water twice a year. “Growers should monitor during the driest time and the wettest time of year because the water table goes up and down,” he said. “I recommend growers monitor the treated water in the greenhouse on a continuous basis. If not on a continuous basis, the water quality should be checked daily.”

Don’t forget maintenance

Jerry van Kampen, inside sales support at Priva North America Inc., said one of the biggest adjustments some growers have to make a er installing a water treatment system is maintaining the system.

“For those growers who installed a water treatment system, they went from not having to do anything to now having to maintain it to ensure it operates optimally. Maintenance of the system needs to be ongoing. Growers should also step up their water quality analysis once they have a treatment system in place.”

van Kampen said even if a grower’s water treatment system consists of only installing a filter, the filter will require regular maintenance to perform at its optimal level.

“Installing a filter is the easiest way to go,” he said. “Maintaining the filter will result in less maintenance in the greenhouse or the eld. The water will be cleaner so valves won’t stick as o en and the irrigation drippers won’t clog as much. But the filter is going to have to be maintained in order for it to be effective.”

For more: Advanced Treatment Technologies, (855) 696-6348; http://advancedtreatmenttechnologies.com.

Priva North America Inc., (903) 562-7351; http://www.priva.ca.

David Kuack is a freelance technical writer in Fort Worth, Texas; dkuack@gmail.com.