Originally published in Issue 12

Proper HVAC Maintenance Delivers Savings and Reliability

By John Zimmerman

Learn what preventive maintenance should be done on a controlled environment agriculture heating, ventilation and air conditioning system and what it can cost you if it’s not.

In Urban Ag News Issue 11, I introduced Jeffrey Orkin, CEO at Greener Roots Farm, a hydroponic controlled environment agriculture operation in Nashville, Tenn. I was monitoring the power consumption of Greener Roots Farm’s heating, ventilation and air conditioning (HVAC) system as part of a case study, when one of the compressors in the system failed. Because I had a power monitor on the system before and after the compressor was replaced, I was able to determine how much energy and money the HVAC system was wasting as a result of the problems that led to the compressor failure.

Preventive maintenance schedule

Before I present data on why Greener Roots Farm’s compressor failed, I’m going to discuss a basic HVAC preventive maintenance (PM) schedule. I’ll also highlight the importance of each maintenance activity and provide variations to the schedule that make sense for indoor growing applications.

HVAC preventive maintenance basics

Three common factors that determine the makeup of an effective PM schedule are:

1. The type of HVAC system.

2. The application the system is serving.

3. The ambient conditions within which the system operates.

These factors determine the type of activities that are required as part of the PM schedule and the frequency with which they need to be performed.

The type of HVAC system used determines the components that require PM. For example, a chilled water system requires a relatively elaborate PM schedule because of the number of complex components in this system. Greener Roots Farm has a direct-expansion (DX) split-system, much like those used in residential applications.

Chilled water system components DX split-system components

Chiller(s) Air handler

Pump(s) Condenser

Cooling tower(s)

Air handler(s)

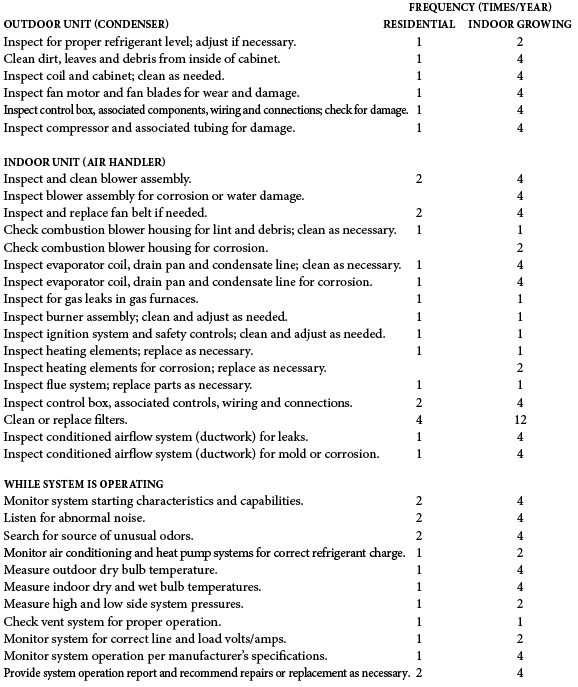

Based on the number of components that require PM, a DX split-system has a much less complex PM schedule than a chilled water system. However, the PM schedule for Greener Roots Farm’s DX split-system differs greatly from a residential application, primarily due to the difference in operation.

The HVAC system for an indoor growing operation needs to operate 24 hours a day and treats a very high latent load (very moist air). Compare that to a residential HVAC system that cycles on and off based on the relative comfort of the space and treats a much lower latent load, thereby reducing wear and tear on the components. Additionally, the high moisture content of the air in indoor growing operations opens the door for issues that residential systems rarely encounter. These include corrosion of metal parts including linkages and drain pans, clogged condensate lines and mold.

The ambient conditions in which a system operates can greatly impact the wear and tear of the system’s components. Greener Roots Farm’s case highlights this fact. The term ambient conditions refer to the immediate surroundings of the system or components of the system. For the purpose of this article, the focus is on the impact ambient conditions have on outdoor components. However, as described above, moist air indoors can negatively impact indoor components as well.

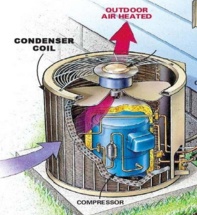

For most systems, components located outdoors are designed to reject the indoor heat to the outside air. In a DX split-system, like at Greener Roots Farm, the outdoor (and heat-rejecting) component is the condenser. In order to reject the heat, the condenser uses a fan to force air across the coil, allowing the heat from the refrigerant inside the coil to be transferred to the cooler outside air (See Figure 1).

When creating a PM schedule for a condenser, the surrounding dirt, dust and debris that can reduce the component’s ability to properly reject the heat must be taken into consideration.

Figure 2 shows how dirt, dust and debris can impact a condenser. Ambient conditions including annual rainfall, direct sunlight and wind have an impact on the life of outdoor components and must be considered when creating a PM schedule.

Sample PM schedule for a DX split-system

Greener Roots Farm case study

There were two reasons that the compressor failed at Greener Roots Farm, both of which are directly related to the system’s ability to reject heat.

1. The outdoor condenser coil was extremely dirty. A dirty condenser coil reduces the airflow across the coil, subsequently reducing the amount of heat that the forced air can remove.

2. The indoor air handler had a loose belt. A loose belt reduces the airflow to the indoor growing space, causing the overall heat content of the return air to rise.

To further complicate things, the condenser at Greener Roots Farm had a two-row coil. This means that even if the perimeter coil (the visible coil) was clean, there is still a possibility that the interior coil was dirty. This is what happened with the Greener Roots Farm condenser (See Figures 3 and 4). The perimeter coil is clean, but the interior coil had not been cleaned for a long time.

Greener Roots Farm was paying a local contractor to do PM on its HVAC system twice a year.

While the sample PM schedule above suggests PM should be done on an HVAC system in an indoor growing setting on a quarterly basis, the coil on the Greener Roots Farm condenser should not have gotten this dirty. Although the hired contractor may have cleaned the perimeter (visible) coil twice a year, it was obvious that that the interior coil had not been cleaned.

Some costs that result from poor PM on an HVAC system are easy to quantify, including the cost of a new compressor, the money wasted for a PM contractor and the downtime associated with fixing the problem. However, the increase in energy cost over time as a result of a slow degrading system is very hard to quantify. Luckily for Greener Roots Farm, a power monitor was placed on the system for three days (spanning four calendar days) before the compressor failed.

We continued to monitor the power for 27 days after the compressor was replaced, the coil was cleaned and the belt was replaced The power monitor took readings in 10 minute intervals.

Below is a summary of the results.

Total power (kW) used

Before: 2,498 | After: 1,857 | Delta: (641)

Total energy cost ($0.11)

Before: $274.78 | After: $204.27 | Delta: ($70.51)

Cost per day

Delta: ($23.50)

Greener Roots Farm power monitor data

Before presenting Greener Roots Farm power monitor information, there a few disclaimers about the data.

1. In a deliberate, controlled experiment, three days would not be an adequate time sample, especially to determine the increase in degradation over time. However, three days was the amount of time available.

2. Since the power was being monitored for the last three days before the compressor failed, it can be assumed that these were the most inefficient days and that every day before this three day period would have been incrementally more efficient.

3. Furthermore, the assumption was made that this indoor growing facility was operated the same for both time samples.

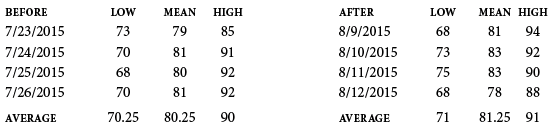

4. In order to make an accurate comparison, a four calendar-day sample of the post repair time period was chosen that had approximately the same outside air conditions.

Here is a summary of those conditions:

Temperature comparison (Fahrenheit)

Looking at the outside air temperature comparison, temperatures during the time sample after repairs were made were slightly higher, but the power usage was still less.

Lessons learned

The Greener Roots Farm HVAC case study is not a complex, scientific experiment. However, it is a simple example of how poor preventive maintenance can cost growers money in the long run. This case study should also serve as a reminder to ensure that contractors are performing the work they were hired to do.

Many of the preventive maintenance activities for HVAC systems, including cleaning coils, can be done by most employees with materials available at local hardware stores. I recommend growers do some of these activities. This will allow them to become familiar with the results should a professional HVAC technician be hired to do the maintenance.

About Harvest Air

Harvest Air was founded by Chris Whaley and John Zimmerman in July 2015. Both Chris and John are registered professional engineers with a combined 30+ years of experience designing, estimating and managing the installation of large-scale commercial heating, ventilating and air conditioning (HVAC) systems for a wide range of industries.

Controlled environment agriculture (CEA) requires a sophisticated farming process to ensure that crops receive the proper amount of water and nutrients in order to optimize yield. While it might appear that the farming techniques used in CEA are well designed and sophisticated, Chris and John discovered that many of the HVAC systems used in CEA are not adequate. By applying proven principles and knowledge gained from their experience, Harvest Air’s HVAC solutions are extremely efficient and reliable, allowing farmers to focus on their crops and not the infrastructure that supports them.

John Zimmerman, PE

Co-Founder and President

john.zimmerman@harvestairllc.com

John Zimmerman obtained a bachelor’s degree in mechanical engineering from the University of Texas-Austin and a master’s degree in building construction management from Purdue University. He is a registered professional engineer in Texas.

Chris Whaley, PE

Co-Founder and CEO

chris.whaley@harvestairllc.com

Chris Whaley obtained a bachelor’s degree in mechanical engineering from the University of Oklahoma and is a registered professional engineer in Texas.

Both John and Chris have spent their careers designing, selling and managing the installation of mechanical systems for large-scale commercial buildings for some of the largest mechanical design-build companies in the United States.

2 Comments

About 48% of your utility bill goes to heating and cooling A well-maintained HVAC system uses less energy lowering your utility bills Regular maintenance can help prevent small problems from becoming costly repairs

Thanks for information. Great tips!!!